1957: Company formation

The family business Plastro Mayer in the Swabian Alb was founded by Dr. Franz Grupp on April 05, 1957 as a former subsidiary of the textile company Trigema. The name is composed of Plastro Trochtelfingen and the last name of Josef Mayer (founder of Trigema).

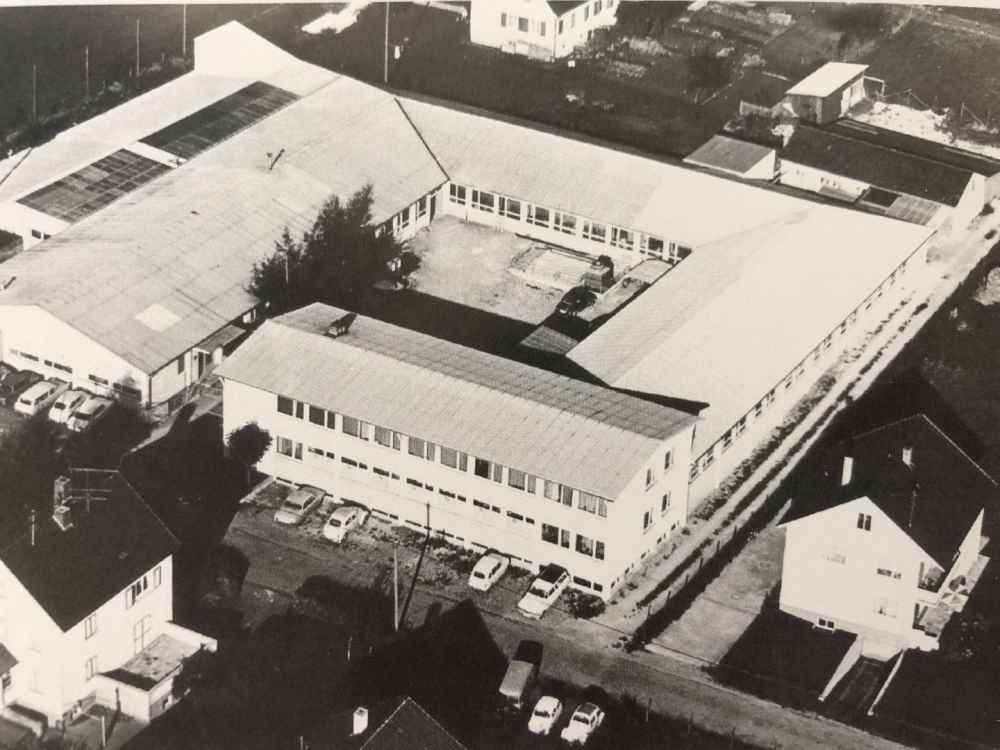

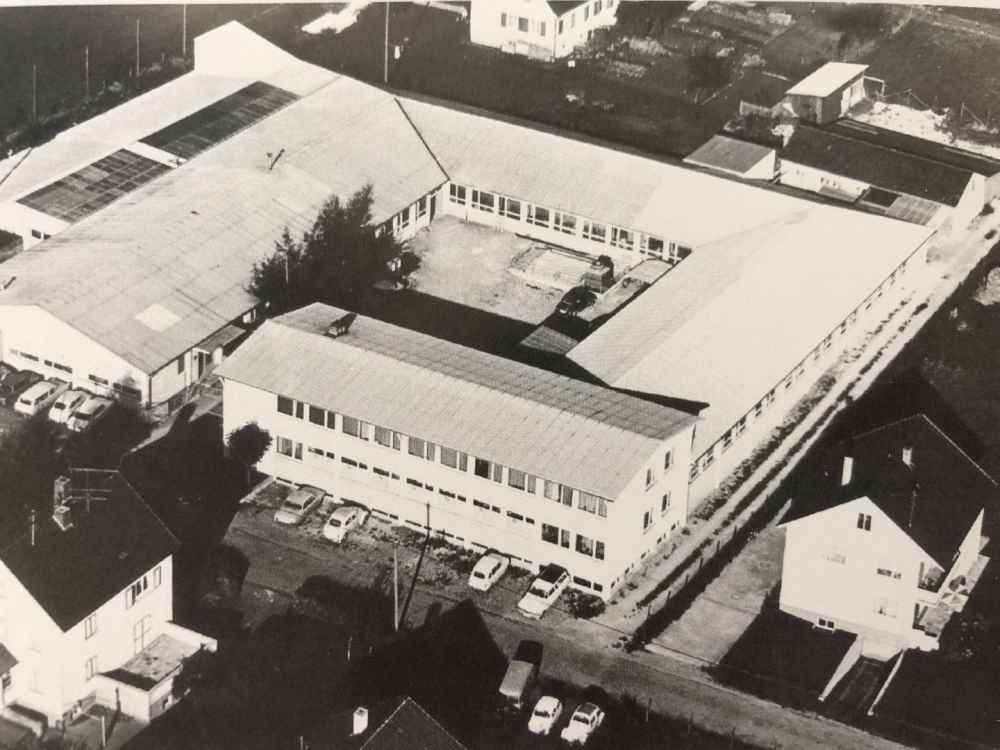

1959-1962: Production expansion + new administration building

The first injection molding machines for connector production were set up. Cable production was also expanded. The demand for manufactured parts made the construction of a new administration building necessary.

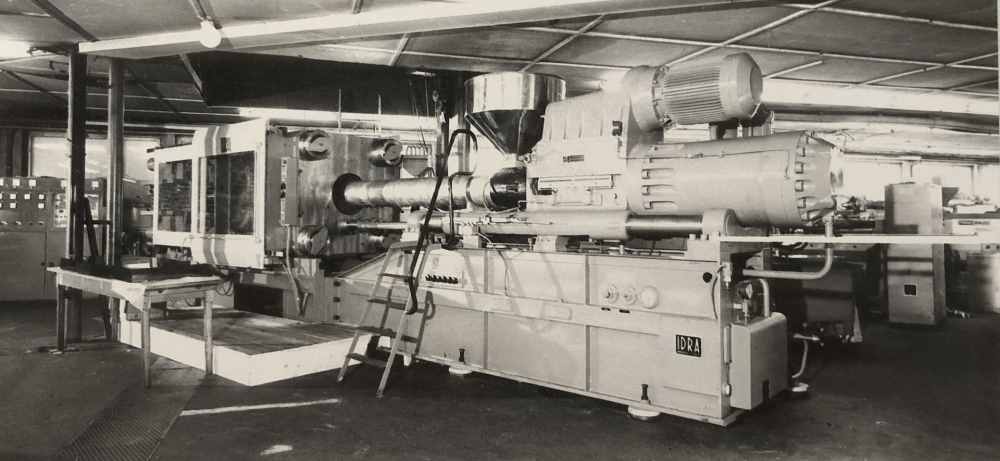

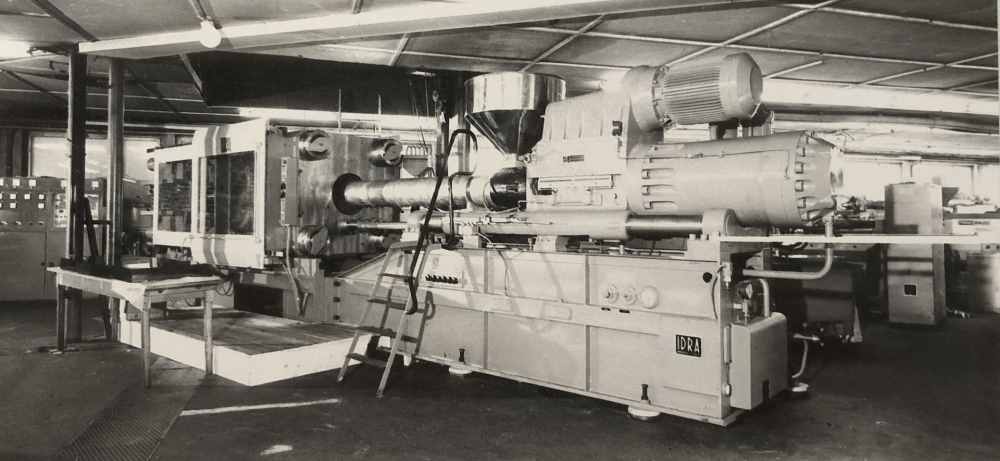

1967: Injection molded parts up to 4 kg

The expansion of the production range in injection molding, such as TV and radio parts up to 4 kg injection weight, made it necessary to purchase larger injection molding machines and molds.

1976: Independent company + new construction of injection molding hall

Since 1976 Plastro Mayer has been a separate and independent company with its exclusive location in Trochtelfingen. The number of employees and turnover developed upwards, making a new production hall for injection molding necessary. Subsequent work such as screen printing, hot stamping, ultrasonic and mirror welding now expanded the production program.

1977: New extrusion production branch

Extrusion of all types of profiles was added as a new branch of production in 1977.

1979: Entry Johannes Grupp

After graduating in Business Administration on October 10,1979, Johannes Grupp stepped in as managing partner.

1985: New construction injection molding hall + warehouse

The production programs were continuously supplemented, further specified and aligned to customer requirements. Developments suitable for plastics in the company's own design office opened up new customer groups. The assembly of electrical cables was expanded and largely automated. This necessitated a further expansion of production and the construction of a warehouse.

1986: Sole owner

Since the retirement of Dr. Franz Grupp, his son Johannes Grupp has been managing the company Plastro Mayer GmbH as sole owner and managing partner.

1987: New production branch complete assembly

With the equipment manufacturing as a combination of injection molded parts and electric cable, an extended manufacturing spectrum could be offered to the customers. The administration building was completely rebuilt and redesigned as required.

1989: Plant expansion

The continuous growth created additional space requirements for production and logistics, which were met in 1989 by the construction of another production building and a warehouse with a total of 3500 m². The new buildings made it possible to expand and optimize individual areas.

1990: Central material handling system

The equipment of all injection molding machines with robot systems and the material feed via a central material conveyor system were milestones in the automation of injection molding production. In parallel, the quality system was continuously expanded in all areas.

1995: Purchase plant 2

Since Plastro Mayer was not granted permission for the urgently needed expansion at its previous location in Mühltalstraße, the existing company building of a former textile company with 3,400 m² of usable space and a total of 2.1 hectares of land was acquired in the Trochtelfingen industrial park in 1995.

1996: Certification according to DIN EN ISO 9000

Plastro Mayer's quality management system has been certified according to DIN EN ISO 9000 since 1996.

1997: Expansion of plant 2 by 4,200 m²

Shortly after the acquisition of the second plant, another expansion of the production area became necessary. In August 1997, the entire cable production was relocated to the buildings in the new Plant 2. At the same time, the vertical range of manufacture in cable production was increased by the extrusion of cores and cables and the fully automatic cable assembly was expanded.

2004: New construction of dispatch warehouse

With the aim of optimizing operations and processes and meeting the changing requirements of customers, Plant 1 was expanded to include a 1000 m² shipping and storage hall.

2006: New mold warehouse plant 1 + logistics warehouse plant 2

A short time later, the expansion with a modern mold warehouse with 700 m² in plant 1 and a logistics warehouse with 2100 m² in plant 2 was necessary.

2007: 50 years PM

In its anniversary year 2007, Plastro Mayer invested, among other things, in ten new injection molding machines including robots, so that 50 production lines with a clamping force of 35-1100 t were available there. Three of these machines are equipped for 2K technology. This increases the possible injection weight to 4.9 kg!

2011: Entry Isabel Grupp

The third generation has been represented in the company since 01.03.2011 by daughter Isabel Grupp-Kofler (Master in International Business). The father-daughter team has jointly managed Plastro Mayer since 2015.

Today

Today, the company has around 250 employees and a production area of over 22,000 m². Production in the four areas - "everything from a single source" - is Plastro Mayer's unique selling point on the German market. No other supplier currently offers this USP in this combination.

-

1957: Company formation

The family business Plastro Mayer in the Swabian Alb was founded by Dr. Franz Grupp on April 05, 1957 as a former subsidiary of the textile company Trigema. The name is composed of Plastro Trochtelfingen and the last name of Josef Mayer (founder of Trigema).

-

1959-1962: Production expansion + new administration building

The first injection molding machines for connector production were set up. Cable production was also expanded. The demand for manufactured parts made the construction of a new administration building necessary.

-

1967: Injection molded parts up to 4 kg

The expansion of the production range in injection molding, such as TV and radio parts up to 4 kg injection weight, made it necessary to purchase larger injection molding machines and molds.

-

1976: Independent company + new construction of injection molding hall

Since 1976 Plastro Mayer has been a separate and independent company with its exclusive location in Trochtelfingen. The number of employees and turnover developed upwards, making a new production hall for injection molding necessary. Subsequent work such as screen printing, hot stamping, ultrasonic and mirror welding now expanded the production program.

-

1977: New extrusion production branch

Extrusion of all types of profiles was added as a new branch of production in 1977.

-

1979: Entry Johannes Grupp

After graduating in Business Administration on October 10,1979, Johannes Grupp stepped in as managing partner.

-

1985: New construction injection molding hall + warehouse

The production programs were continuously supplemented, further specified and aligned to customer requirements. Developments suitable for plastics in the company's own design office opened up new customer groups. The assembly of electrical cables was expanded and largely automated. This necessitated a further expansion of production and the construction of a warehouse.

-

1986: Sole owner

Since the retirement of Dr. Franz Grupp, his son Johannes Grupp has been managing the company Plastro Mayer GmbH as sole owner and managing partner.

-

1987: New production branch complete assembly

With the equipment manufacturing as a combination of injection molded parts and electric cable, an extended manufacturing spectrum could be offered to the customers. The administration building was completely rebuilt and redesigned as required.

-

1989: Plant expansion

The continuous growth created additional space requirements for production and logistics, which were met in 1989 by the construction of another production building and a warehouse with a total of 3500 m². The new buildings made it possible to expand and optimize individual areas.

-

1990: Central material handling system

The equipment of all injection molding machines with robot systems and the material feed via a central material conveyor system were milestones in the automation of injection molding production. In parallel, the quality system was continuously expanded in all areas.

-

1995: Purchase plant 2

Since Plastro Mayer was not granted permission for the urgently needed expansion at its previous location in Mühltalstraße, the existing company building of a former textile company with 3,400 m² of usable space and a total of 2.1 hectares of land was acquired in the Trochtelfingen industrial park in 1995.

-

1996: Certification according to DIN EN ISO 9000

Plastro Mayer's quality management system has been certified according to DIN EN ISO 9000 since 1996.

-

1997: Expansion of plant 2 by 4,200 m²

Shortly after the acquisition of the second plant, another expansion of the production area became necessary. In August 1997, the entire cable production was relocated to the buildings in the new Plant 2. At the same time, the vertical range of manufacture in cable production was increased by the extrusion of cores and cables and the fully automatic cable assembly was expanded.

-

2004: New construction of dispatch warehouse

With the aim of optimizing operations and processes and meeting the changing requirements of customers, Plant 1 was expanded to include a 1000 m² shipping and storage hall.

-

2006: New mold warehouse plant 1 + logistics warehouse plant 2

A short time later, the expansion with a modern mold warehouse with 700 m² in plant 1 and a logistics warehouse with 2100 m² in plant 2 was necessary.

-

2007: 50 years PM

In its anniversary year 2007, Plastro Mayer invested, among other things, in ten new injection molding machines including robots, so that 50 production lines with a clamping force of 35-1100 t were available there. Three of these machines are equipped for 2K technology. This increases the possible injection weight to 4.9 kg!

-

2011: Entry Isabel Grupp

The third generation has been represented in the company since 01.03.2011 by daughter Isabel Grupp-Kofler (Master in International Business). The father-daughter team has jointly managed Plastro Mayer since 2015.

-

Today

Today, the company has around 250 employees and a production area of over 22,000 m². Production in the four areas - "everything from a single source" - is Plastro Mayer's unique selling point on the German market. No other supplier currently offers this USP in this combination.