Injection molding at Plastro Mayer: from the injection mold to production

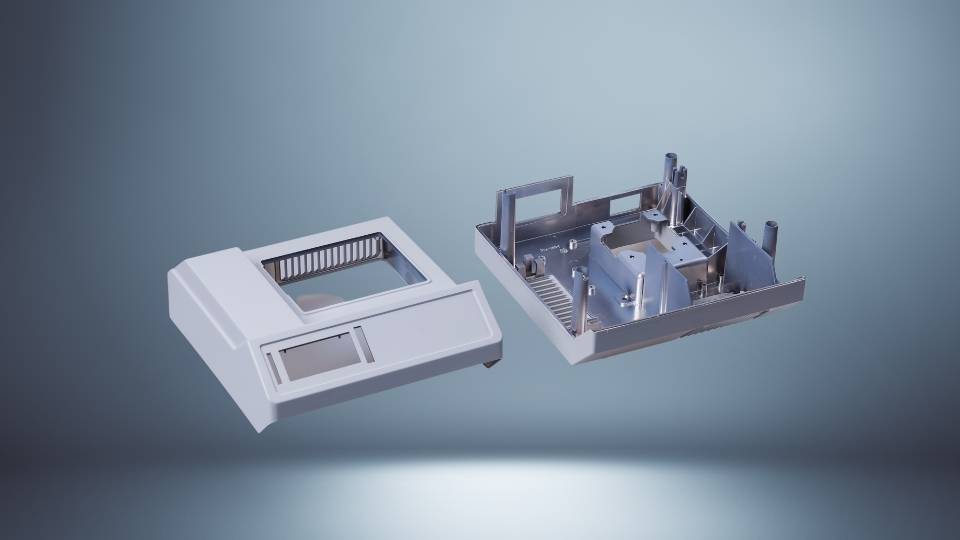

Plastic injection molding, also known as injection moulding, is a process for manufacturing high-quality plastic parts. From tooling to part production, Plastro Mayer offers an accurate and efficient manufacturing solution. Our customized injection moulding tools and our precisely moulded plastic parts of the highest quality have made us a leading and reliable plastic injection moulding manufacturer for many years.

The injection molding process consists of several steps:

- tool preparation: first, the injection mold is prepared in the tool shop with cleaning and insertion into the injection molding machine. The appropriate parameters such as temperature and pressure are then set.

- material melting: The thermoplastic is melted in a heated cylinder.

- injection phase: Under high pressure, the molten material is injected into the hollow mold (cavity) of the tool via the injection unit. It is important that the material fills all areas of the mold and that no air pockets are formed.

- cooling phase and solidification: During this phase, the material cools and solidifies, forming the final part. The cooling time is a critical factor for the cycle time and the quality of the final product.

- mold opening and part removal: The mold is opened and the finished part is removed. This can be done manually or automatically.

- post-processing: In many cases, the molded parts require post-processing after injection molding. This can include the removal of sprues, grinding, painting or other surface treatments.

- re-injection: The process starts all over again.

Injection molding can be carried out using single-component injection molding or multi-component injection molding. Both processes are ideal for the production of large series of plastic parts. However, the production of molded parts in small batches is also no problem for us. With our modern injection molding machines, we guarantee a precise, efficient and automated process in every case.

Plastro Mayer is a full-service provider with the business areas of injection molding, cables, device assembly and toolmaking, offering everything to do with plastic injection molding and production from a single source. With us, you also have the option of using the services of individual business units.

We would be happy to receive your inquiries so that we can jointly develop an individual injection-molded plastic solution for the production of your plastic parts. We look forward to convincing you of our services. You can also take a look at the list of our numerous references.

Get in touch with our plastic injection molding experts today!

The right plastic: injection molding to suit your order

As an experienced plastic injection molding manufacturer, we have a broad and in-depth knowledge of a wide range of industries. In our injection molding production, we process various high-quality materials in all colors and strengths. The following main material groups are available to you:

- Thermoplastics

- elastomers

We have a large selection of thermoplastics in stock and process them using single-component and multi-component injection molding. These thermoplastics include, among others

- Polyamide (PA)

- Polystyrene (PS)

- Polyethylene (PE)

- Polypropylene (PP)

- Polymethyl methacrylate (PMMA)

- Acrylonitrile butadiene styrene (ABS)

- Polycarbonate (PC)

- Polyoxymethylene (POM)

In addition, we are also able to use glass fiber reinforced material, glass bead material, material with added minerals, carbon fibers or wood fibers. Our range also includes heat-resistant, fire-protected, food-safe and drinking water-approved materials. We also offer rubber molded parts made of elastomer (NR) and plastic injection molded parts made of bioplastic or biopolymer, which is made from renewable raw materials.

We process the materials you require in our injection molding machines. If you are not sure which material is best suited for your required molded parts, simply contact our injection molding experts. We will help you select the right material and, thanks to our many years of experience in injection molding, can provide you with expert advice on the suitability of your component. On request, we can also sample your molded part in various materials in order to support you with regard to possible test procedures and in selecting the best solution.

An excerpt of our capabilities in plastic injection molding

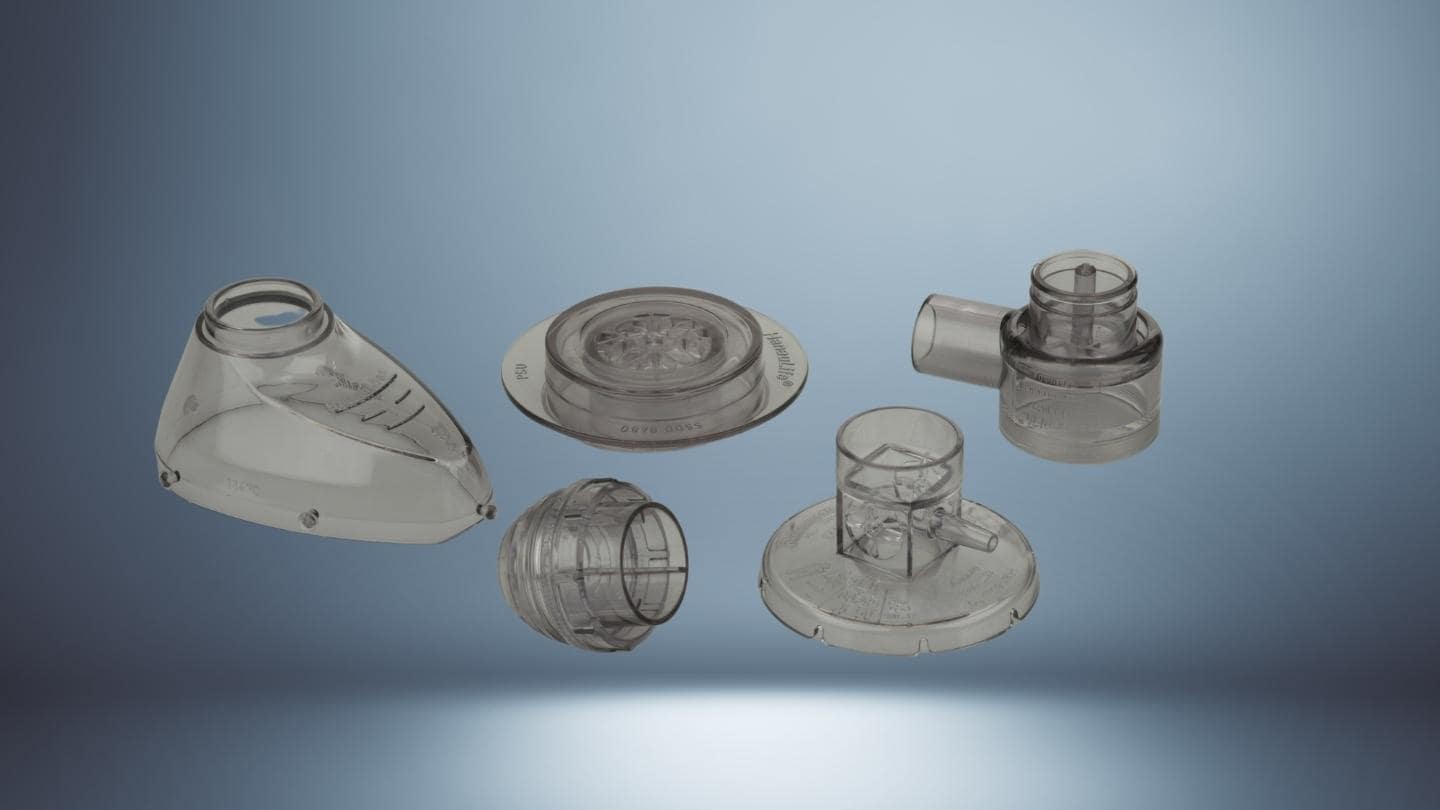

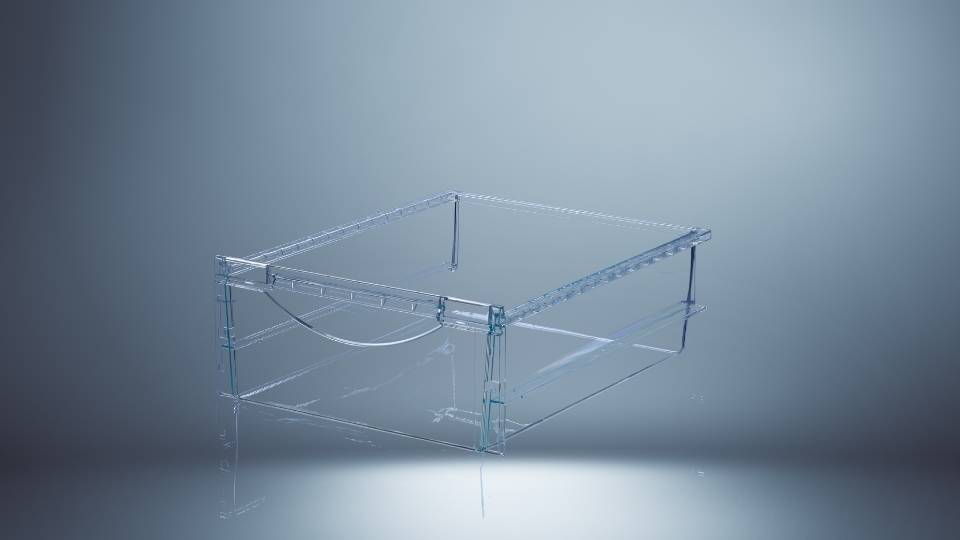

Medical and laboratory technology requires specific components made from high-quality plastic injection molding. Every customer has individual requirements for injection molding and plastics technology.

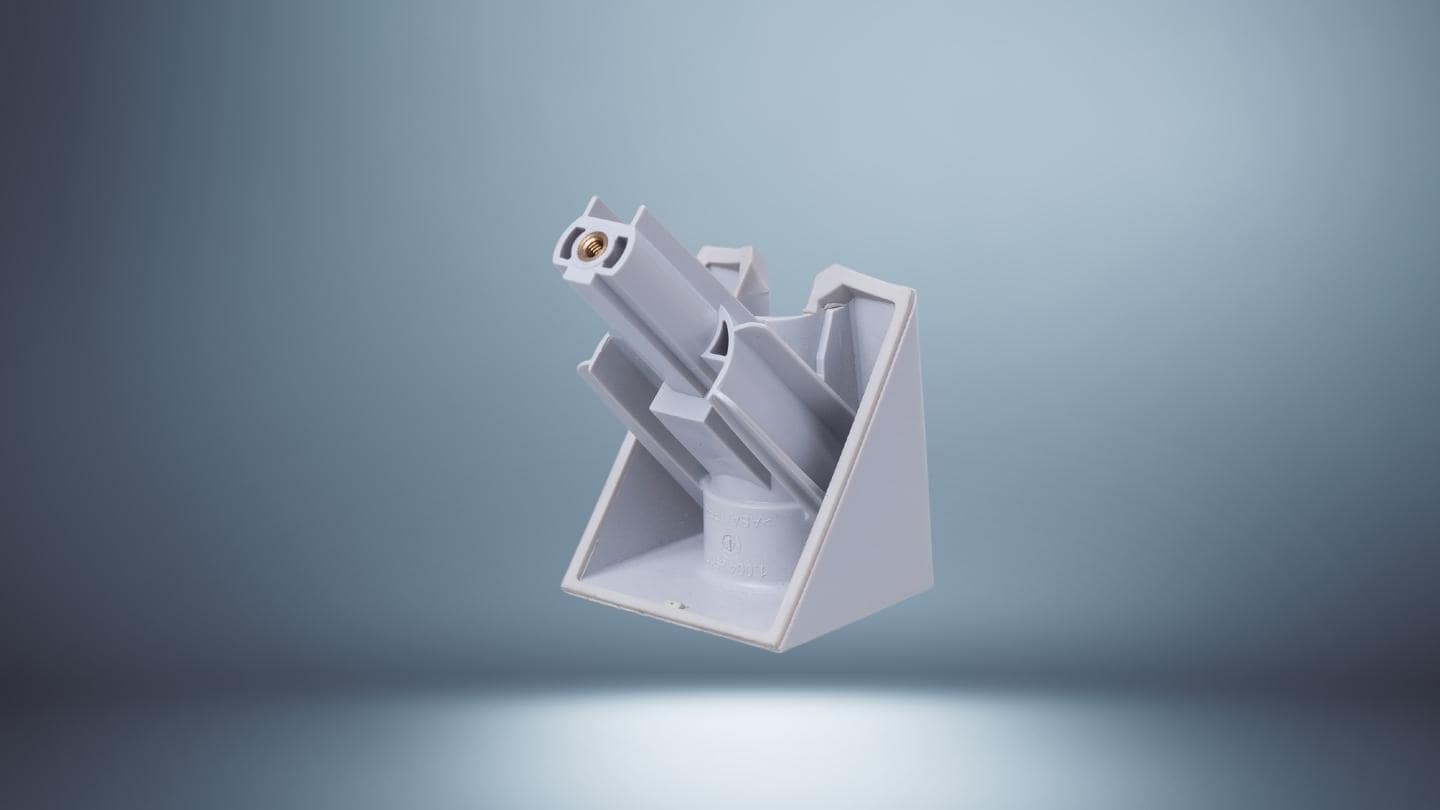

Sophisticated injection molded parts with special requirements for pressure load changes, for example, can be found in filter and water technology. These include complex filter parts with threads, pressure pipes with pressed-in brass bushes and components with tight tolerances.

High standards apply to plastic injection molded parts in the household goods industry. These are frequently used due to their versatility, durability, lightness, heat resistance, ease of molding and resistance to moisture and chemicals.

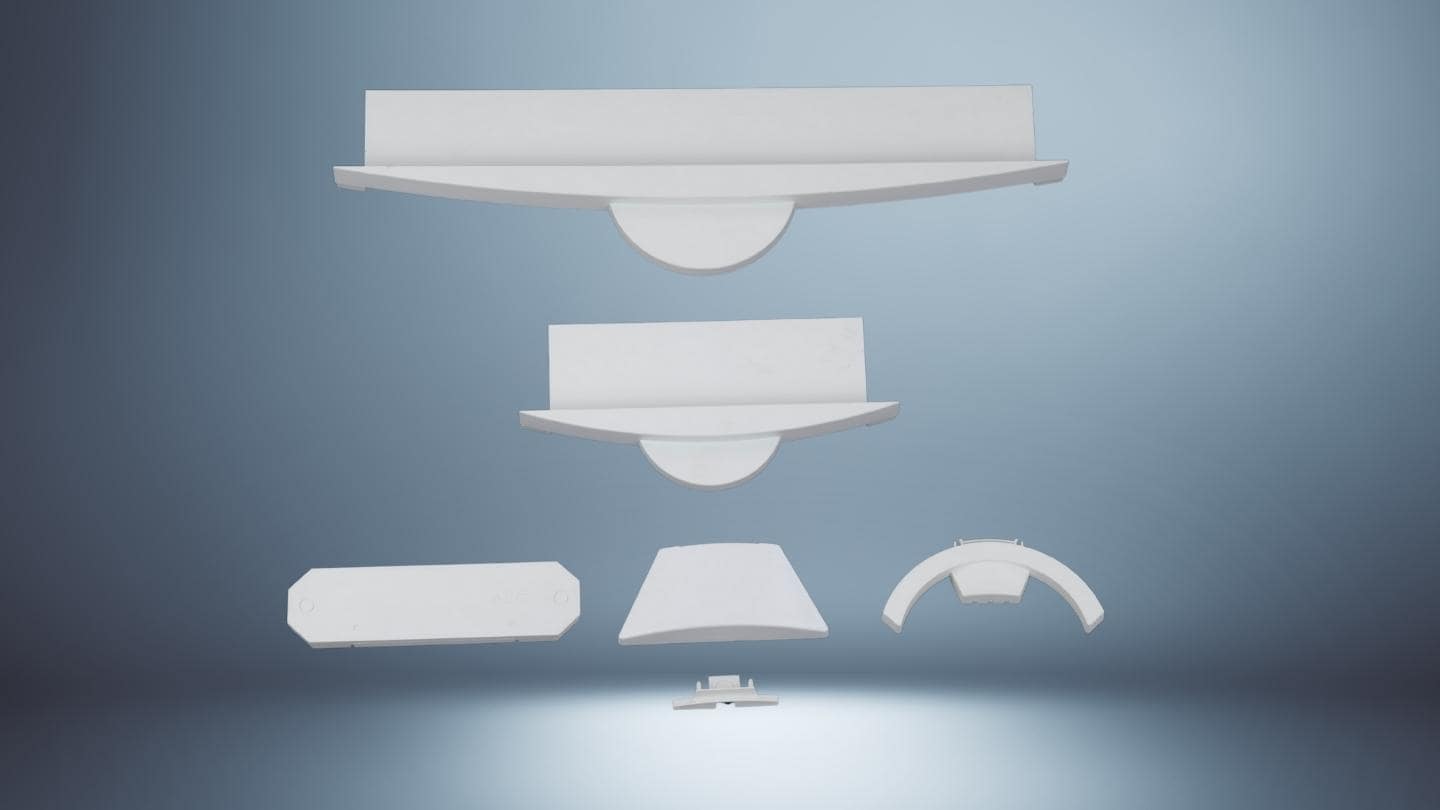

One advantage of plastic parts for chair manufacturing is their strength and individual formability. They are often used to manufacture various components, including seat shells, backrests, armrests and leg braces.

The automotive industry also relies on high-quality plastic injection molding. This is used in a wide variety of areas to improve both the performance and aesthetics of vehicles. Plastics allow manufacturers to create complex shapes and designs through injection molding.

The main advantage of molded parts produced by injection molding for the lighting industry is their versatility and heat resistance. As they can be produced in almost any desired shape, this allows many possibilities for creative designs.

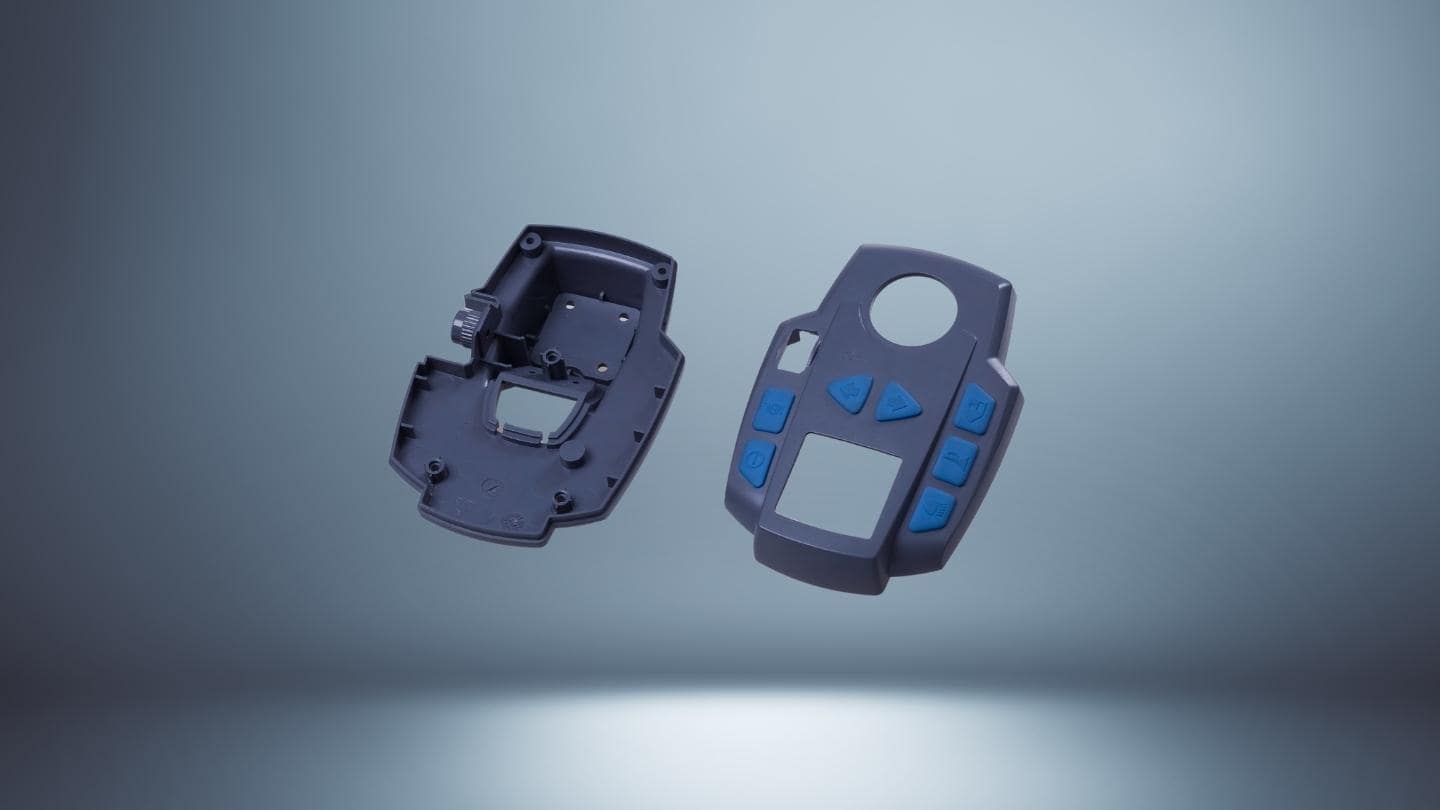

The use of injection-molded plastic parts for the production of power tools has increased significantly in recent years. Among other things, this is due to the decisive advantage that injection-molded plastic is significantly lighter than metal despite its durable strength.

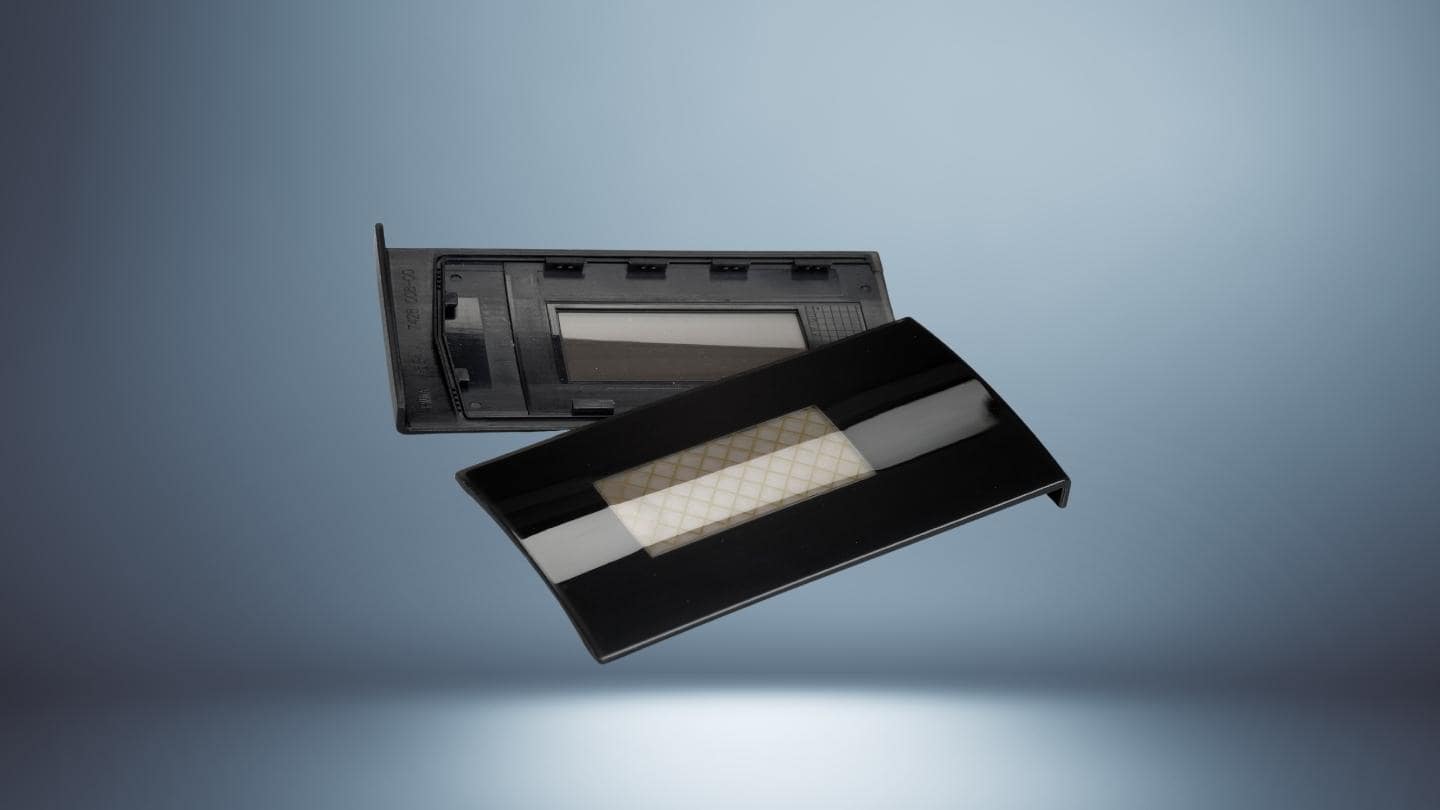

Two-component injection molding is a process used to produce components with different material properties or colors. Two different plastics are joined together in a single injection molding process without additional adhesives or weld seams. The result is increased stability and product quality.